|

Ningbo Tongchuang Strong Magnet Material Co., Ltd.

|

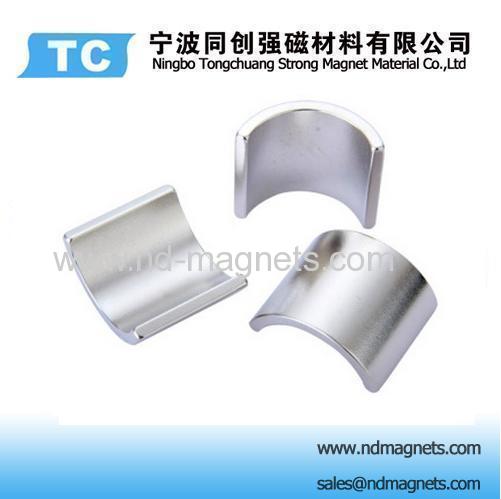

brushless motors permanent magnets

| Price: | 0.1~21.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P,WU |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. Low wight loss magnets

2. L35EHT, all customerized

3.brushless motors

4. Original permanent magnet factory

5. any samples orders are available

Product name:brushless motors permanent magnets

Model No.ND-ARC013

brushless motors permanent magnets

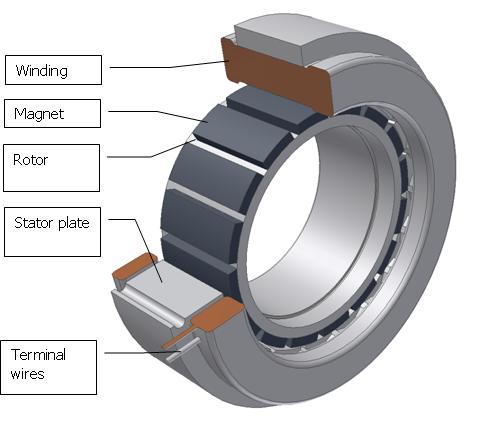

Brushless motor Cylindrical construction

outside rotor inside rotor

Magnets grade: Grade L38SHT,L42UHT,L35UHT,L35EHT, ( customized)

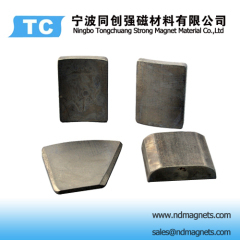

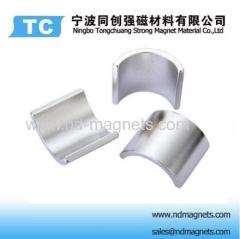

Magnets size : Customized arc segment shape.

Magnetism direction :paried by thickness

Magnets coating :Cr3+ Zn, Nickel , Epoxy etc according to customers' requirements

Application: brushless fan motor and some other brushless motors

Max working Temp: up to 230°C.

1.As poor corrosion resistance of Iron-base and Nd-rich grain boundary, NdFeB magnets can't be used until plated. Comparing with the expansion of elevator, wind turbines and permanent motors application, the customers need higher requirement on corrosion resistance of NdFeB magnets. Because the glue cohesiveness of un-plated products is much better than the plated products, Un-plated products will be better in the security. Now there are more and more customers want to use the un-plated magnets. Considering this situation, after the continuous innovation and study, our company developed ultra-low weight loss magnets (the unit of weight loss test is mg/cm2, how much milligram losing per Square centimeter). Generally speaking, the weight loss test is over 150mg/cm2 in the NdFeB industry. There is a great difference due to different Material formulation and manufacturing process. While some of our products can reach to 1mg/cm2, (Testing condition: HAST standard for 168hrs) due to the very low weight loss, the corrosion resistance is excellent, the reliability and working life of these products have been improved obviously. These products can meet the strict requirement of corrosion resistance in the application of permanent motors and other fields. They are mainly used in elevator, radar, wind generators, military aerospace, industrial motors and other fields.

2. Application which needs Low weight loss magnets

Low weight loss magnets are mainly used in elevator, radar, wind turbine generators, tide Generators, marsh gas generators, military aerospace, industrial motors and other fields.

3. Some weight loss data of our magnets

Test condition | Standard result | TC Products | |

USA Standard ( PCT) | 121℃±1℃,2atm,95%RH, 96 hours | <5-10mg/cm2 | _ |

Europe Standard ( HAST) | 130℃±2℃,3atm,95%RH, 168 hours | <2-5mg/cm2 | <1mg/cm2 |

Note*: the test sample size is 10X10X10mm or Dia 10X10mm

AS an original permanent magnet factory, we are the TOP 5 neodymium magnet supplier in Ningbo. whith our professional technical team. which has rich experiences in BLCC motor manufacturing. All our magnets are offered according to customer's design.Thus, any samples orders are available in our plant. We are very pleased to help customs in any new projects.

Some work shop in our plant

Our advantages: 1. Original factory with professional technical and service.

2. Strict quality control systems under certification TS16949 and ISO 9001

3. Latest facilities to support R&D, quality control, process control, final product inspection

4. Very low prices due to our production well controlled , process optimization,

5, Fast lead time

6. Motto: partnership with all customers

some other arc segment magnets used in brushless motors.