|

Ningbo Tongchuang Strong Magnet Material Co., Ltd.

|

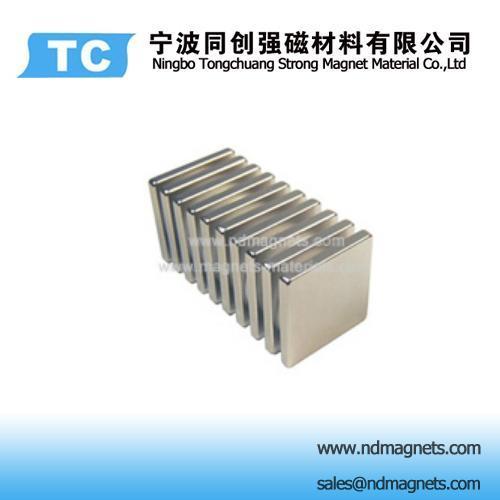

Neodymium Block Magnets grade N52

| Price: | 0.1~10.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

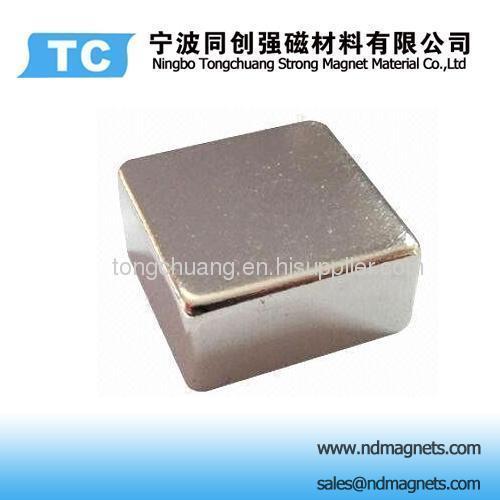

1.Block Neodymium Magnet

2. Strong pulling force

3. Nickel

4. high quality

5. customized products ...

Product name: Neodymium Block Magnet grade N50

Model No.ND-BLOCK 018

Neodymium Block Magnet grade N50

Some popular block magnets

| No. | Grade | Size(mm) | Magnetizm Direction | Coating |

| 1 | N42 | 10x10x5mm | 5mm | NiCuNi |

| 2 | N45 | 20X10X8mm | 8mm | Cr3+Zn |

| 3 | N40 | 25x25x10mm | 10mm | Nickel |

| 4 | N48 | 50X25X20mm | 20mm | Epoxy |

| 5 | N42 | 80x50x30mm | 30mm | NiCuNi |

| 6 | N42H | 76X25X15mm | 15mm | Cr+Zn |

| 7 | N45H | 50X25X12mm | 12mm | NiCuNi |

| 8 | N42 | 76.2X50.8x25.4mm | 25.4mm | NiCuNi |

| 9 | N45 | 50.8X25.4X12.7mm | 12.7mm | NiCuNi |

| 10 | N48 | 25.4X12.7X6.35mm | 6.35mm | Epoxy |

| 11 | N42SH | 1"X1"X1" | 1" | Epoxy |

| 12 | N42 | 10X5X3mm | 3mm | Ag |

| 13 | N42 | 80x60x40mm | 40mm | NiCuNi |

| 14 | N45 | 76X50X35mm | 35mm | NiCuNI |

| 15 | N48 | 100x50x50mm | 50mm | NiCuNi |

| 16 | N33UH | 10X5X4mm | 4mm | Nickel |

| 17 | N45M | 25X20X18mm | 18mm | NiCuNi |

| 18 | N42 | 0.5"x0.5"x0.5" | 0.5" | Cr3+Zn |

| Magnetic properties of Sintered NdFeB magnets: | |||||

| Grade | Remanence | Coercive Force | Intrinsic Coercive Force | Max. energy product | Max. |

| Operating | |||||

| Temperature | |||||

| Br | Hcb | Hcj | ( BH ) | Tw | |

| max | |||||

| mT | kA/m | kA/m | kJ/m3 | ||

| (kGs) | (kOe) | (kOe) | (MGOe) | ||

| N35 | 1170-1220 | ≥ 868 | ≥ 955 | 263-287 | 80 °C |

| (11.7-12.2) | ( ≥ 10.9) | ( ≥ 12) | (33-36) | ||

| N38 | 1220-1250 | ≥ 899 | ≥ 955 | 287-310 | 80 °C |

| (12.2-12.5) | ( ≥ 11.3) | ( ≥ 12) | (36-39) | ||

| N40 | 1250-1280 | ≥ 907 | ≥ 955 | 302-326 | 80 °C |

| (12.5-12.8) | ( ≥ 11.4) | ( ≥ 12) | (38-41) | ||

| N42 | 1280-1320 | ≥ 915 | ≥ 955 | 318-342 | 80 °C |

| (12.8-13.2) | ( ≥ 11.5) | ( ≥ 12) | (40-43) | ||

| N45 | 1320-1380 | ≥ 923 | ≥ 955 | 342-366 | 80 °C |

| (13.2-13.8) | ( ≥ 11.6) | ( ≥ 12) | (43-46) | ||

| N48 | 1380-1420 | ≥ 923 | ≥ 876 | 366-390 | 80 °C |

| (13.8-14.2) | ( ≥ 11.6) | ( ≥ 12) | (46-49) | ||

| N50 | 1400-1450 | ≥ 796 | ≥ 876 | 382-406 | 80 °C |

| (14.0-14.5) | ( ≥ 10.0) | ( ≥ 11) | (48-51) | ||

| N52 | 1430-1480 | ≥ 796 | ≥ 876 | 398-422 | 60°C |

| (14.3-14.8) | ( ≥ 10.0) | ( ≥ 11) | (50-53) | ||

| 35M | 1170-1220 | ≥ 868 | ≥ 1114 | 263-287 | 100 °C |

| (11.7-12.2) | ( ≥ 10.9) | ( ≥ 14) | (33-36) | ||

| 38M | 1220-1250 | ≥ 899 | ≥ 1114 | 287-310 | 100 °C |

| (12.2-12.5) | ( ≥ 11.3) | ( ≥ 14) | (36-39) | ||

| 40M | 1250-1280 | ≥ 923 | ≥ 1114 | 302-326 | 100 °C |

| (12.5-12.8) | ( ≥ 11.6) | ( ≥ 14) | (38-41) | ||

| 42M | 1280-1320 | ≥ 955 | ≥ 1114 | 318-342 | 100 °C |

| (12.8-13.2) | ( ≥ 12.0) | ( ≥ 14) | (40-43) | ||

| 45M | 1320-1380 | ≥ 995 | ≥ 1114 | 342-366 | 100 °C |

| (13.2-13.8) | ( ≥ 12.5) | ( ≥ 14) | (43-46) | ||

| 48M | 1370-1430 | ≥ 1027 | ≥ 1114 | 366-390 | 100 °C |

| (13.7-14.3) | ( ≥ 12.9) | ( ≥ 14) | (46-49) | ||

| 50M | 1400-1450 | ≥ 1033 | ≥ 1114 | 382-406 | 100 °C |

| (14.0-14.5) | ( ≥ 13.0) | ( ≥ 14) | (48-51) | ||

| 35H | 1170-1220 | ≥ 868 | ≥ 1353 | 263-287 | 120 °C |

| (11.7-12.2) | ( ≥ 10.9) | ( ≥ 17) | (33-36) | ||

| 38H | 1220-1250 | ≥ 899 | ≥ 1353 | 287-310 | 120 °C |

| (12.2-12.5) | ( ≥ 11.3) | ( ≥ 17) | (36-39) | ||

| 40H | 1250-1280 | ≥ 923 | ≥ 1353 | 302-326 | 120 °C |

| (12.5-12.8) | ( ≥ 11.6) | ( ≥ 17) | (38-41) | ||

| 42H | 1280-1320 | ≥ 955 | ≥ 1353 | 318-342 | 120 °C |

| (12.8-13.2) | ( ≥ 12.0) | ( ≥ 17) | (40-43) | ||

| 45H | 1320-1360 | ≥ 963 | ≥ 1353 | 342-366 | 120 °C |

| (13.2-13.6) | ( ≥ 12.1) | ( ≥ 17) | (43-46) | ||

| 48H | 1370-1430 | ≥ 955 | ≥ 1353 | 366-390 | 120 °C |

| (13.7-14.3) | ( ≥ 12.5) | ( ≥ 17) | (46-49) | ||

| 35SH | 1170-1220 | ≥ 876 | ≥ 1592 | 263-287 | 150 °C |

| (11.7-12.2) | ( ≥ 11.0) | ( ≥ 20) | (33-36) | ||

| 38SH | 1220-1250 | ≥ 907 | ≥ 1592 | 287-310 | 150 °C |

| (12.2-12.5) | ( ≥ 11.4) | ( ≥ 20) | (36-39) | ||

| 40SH | 1240-1280 | ≥ 939 | ≥ 1592 | 302-326 | 150 °C |

| (12.5-12.8) | ( ≥ 11.8) | ( ≥ 20) | (38-41) | ||

| 42SH | 1280-1320 | ≥ 987 | ≥ 1592 | 318-342 | 150 °C |

| (12.8-13.2) | ( ≥ 12.4) | ( ≥ 20) | (40-43) | ||

| 45SH | 1320-1380 | ≥ 1003 | ≥ 1592 | 342-366 | 150 °C |

| (13.2-13.8) | ( ≥ 12.6) | ( ≥ 20) | (43-46) | ||

| 28UH | 1040-1080 | ≥ 764 | ≥ 1990 | 207-231 | 180 °C |

| (10.4-10.8) | ( ≥ 9.6) | ( ≥ 25) | (26-29) | ||

| 30UH | 1080-1130 | ≥ 812 | ≥ 1990 | 223-247 | 180 °C |

| (10.8-11.3) | ( ≥ 10.2) | ( ≥ 25) | (28-31) | ||

| 33UH | 1130-1170 | ≥ 852 | ≥ 1990 | 247-271 | 180 °C |

| (11.3-11.7) | ( ≥ 10.7) | ( ≥ 25) | (31-34) | ||

| 35UH | 1180-1220 | ≥ 860 | ≥ 1990 | 263-287 | 180 °C |

| (11.8-12.2) | ( ≥ 10.8) | ( ≥ 25) | (33-36) | ||

| 38UH | 1220-1250 | ≥ 876 | ≥ 1990 | 287-310 | 180 °C |

| (12.2-12.5) | ( ≥ 11.0) | ( ≥ 25) | (36-39) | ||

| 40UH | 1250-1280 | ≥ 899 | ≥ 1990 | 302-326 | 180 °C |

| (12.5-12.8) | ( ≥ 11.3) | ( ≥ 25) | (38-41) | ||

| 42UH | 1280-1320 | ≥ 899 | ≥ 1990 | 318-342 | 180 °C |

| (12.8-13.2) | ( ≥ 11.3) | ( ≥ 25) | (40-43) | ||

| 28EH | 1040-1080 | ≥ 780 | ≥ 2388 | 207-231 | 200 °C |

| (10.4-10.8) | ( ≥ 9.8) | ( ≥ 30) | (26-29) | ||

| 30EH | 1080-1130 | ≥ 812 | ≥ 2388 | 223-247 | 200 °C |

| (10.8-11.3) | ( ≥ 10.2) | ( ≥ 30) | (28-31) | ||

| 33EH | 1130-1170 | ≥ 876 | ≥ 2388 | 247-271 | 200 °C |

| (11.3-11.7) | ( ≥ 10.5) | ( ≥ 30) | (31-34) | ||

| 35EH | 1170-1220 | ≥ 876 | ≥ 2388 | 263-287 | 200 °C |

| (11.7-12.2) | ( ≥ 11.0) | ( ≥ 30) | (33-36) | ||

| 38EH | 1220-1250 | ≥ 899 | ≥ 2388 | 287-310 | 200 °C |

| (12.2-12.5) | ( ≥ 11.3) | ( ≥ 30) | (36-39) | ||

| 40EH | 1250-1280 | ≥ 899 | ≥ 2388 | 302-326 | 200 °C |

| (12.5-12.8) | ( ≥ 11.3) | ( ≥ 30) | (38-41) | ||

| 28AH | 1040-1080 | ≥ 787 | ≥ 2624 | 207-231 | 230 °C |

| (10.4-10.8) | ( ≥ 9.9) | ( ≥ 33) | (26-29) | ||

| 30AH | (1080-1130) | ≥ 819 | ≥ 2624 | 223-247 | 230 °C |

| (10.8-11.3) | ( ≥ 10.3) | ( ≥ 33) | (28-31) | ||

| 33AH | 1130-1170 | ≥ 843 | ≥ 2624 | 247-271 | 230 °C |

| (11.3-11.7) | ( ≥ 10.6) | ( ≥ 33) | (31-34) | ||

| 35AH | (1170-1220) | ≥ 876 | ≥ 2624 | 263-287 | 230 °C |

| (11.7-12.2) | ( ≥ 11.0) | ( ≥ 33) | (33-36) | ||

| 38AH | 1220-1250 | ≥ 899 | ≥ 2624 | 287-310 | 230 °C |

| (12.2-12.5) | ( ≥ 11.3) | ( ≥ 33) | (36-39) | ||

Block size magnet

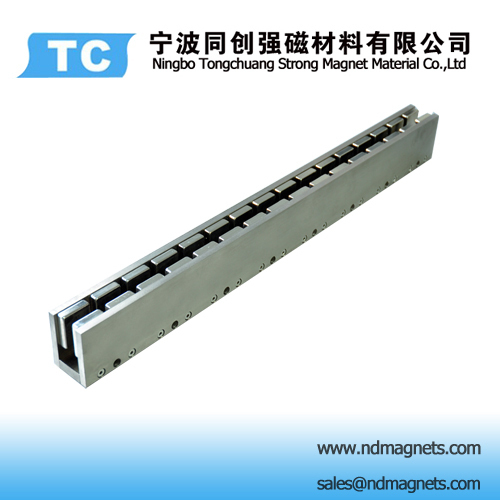

Block magnets used in linear motors

Block Neodymium Magnets are with strong pulling force. the ndfeb magnets are the strongest magnets in the world. compared to the magnets ferrite magnets, Smco magnets, and ALnico Magnet.etc.

Our company is specializing in producing neodymium magnets. All our products are customized. With our products in good quality, we hope to keep a long stable term with all our customers.

We will help you with your order.As an original magnet manufacturer, we offer customized magnets. Usually we ask for the following information.

Material type and grade required.

Size and shape, if available, a sketch or drawing with dimensions and tolerances.

Max working temperature.

Delivered magnetized or unmagnetized? Magnetization direction?

Quantities required.

Coating required (if any)

Information on what you want to use the magnet for.

.

.jpg)