|

Ningbo Tongchuang Strong Magnet Material Co., Ltd.

|

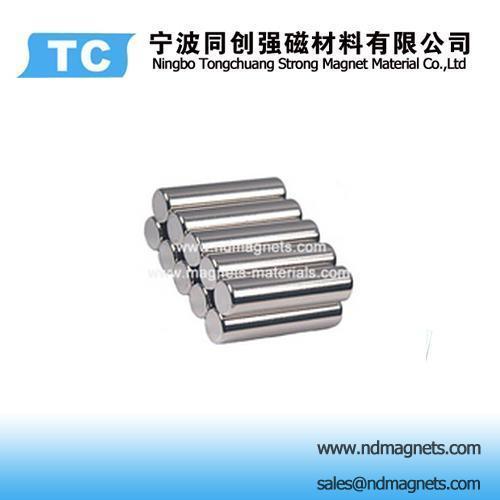

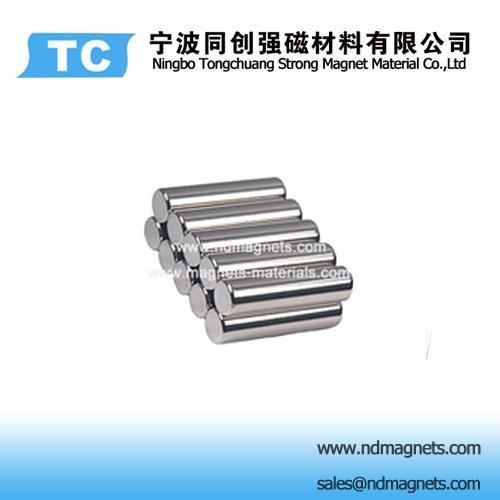

cylinder ndfeb magnets produced

| Price: | 0.1~12.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1magnet grade N42SH

2.customized

3.No Minimum order quantity

4. original factory producing magnets

5.competitive prices

Product name: Cylinder Magnets grade N42SH

Model No.TC-CYL.062

Cylinder Magnets grade N42SH

Specification:

Size: D15X40

Coating: Nickel

Magnetize direction: axial by 40mm

Grade N42SH

Max working Temp:150 Degrees.

Our factory is an original factory specializing in producing middle-high grade magnets( H SH, UH EH...). we are famous in offering high temperature stability products and low weight loss products which are widely using in motors, wind turbines, speakers etc. All our process is under ISO/TS 16949.

We have the complete , advanced test equipments to inspect our products before shipping out

Please refer to some of our advanced test equipments

ICP Analyzer

Oxygen Analyzer

Surface treatment of the magnets

| Surface | Coating | Thickness Um | Color | SST hours | PCT hours |

| Nickel | Ni | 10-20 | Bright | >24-72 | >48 |

| Ni+Cu+Ni | |||||

| Black Nickel | Ni+Cu+Ni | 10-20 | Bright black | >48-96 | >48 |

| Cr3+Zinc | Zn | 5-8 | Bright Blue | >16-48 | |

| Czn | Color | >24-72 | |||

| Tin | Ni+Cu+Ni+Sn | 10-25 | Sliver | >36-72 | >48 |

| Gold | Ni+Cu+Ni+Au | 10-15 | Sliver | >12 | >48 |

| Ag | Ni+Cu+Ni+Ag | 10-15 | Sliver | >12 | >48 |

| Epoxy | Epoxy | 10-25 | Black,Grey | >48 | |

| Ni+Cu+Epoxy | 15-30 | >48-96 | |||

| Zn+Epoxy | 15-25 | >48-96 | |||

| Passivation | 1-3 | Dark Grey | |||

| Phosphated | 1-3 | Dark Grey | |||

colored zinc treatment

Our advantages: 1. Original factory with professional technical and servers.

2. Strict quality control systems under certification TS16949 and ISO 9001

3. Latest facilities to support R&D, quality control, process control, final product inspection

4. Very low prices due to our production well controlled , process optimization,

5, Fast lead time

6. Motto: partnership with all customers

Product flow

Product flow

We will help you with your order.As an original magnet manufacturer, we offer customized magnets. Usually we ask for the following information.

Material type and grade required.

Size and shape, if available, a sketch or drawing with dimensions and tolerances.

Max working temperature.

Delivered magnetized or unmagnetized? Magnetization direction?

Quantities required.

Coating required (if any)

Information on what you want to use the magnet for.

.jpg)