|

Ningbo Tongchuang Strong Magnet Material Co., Ltd.

|

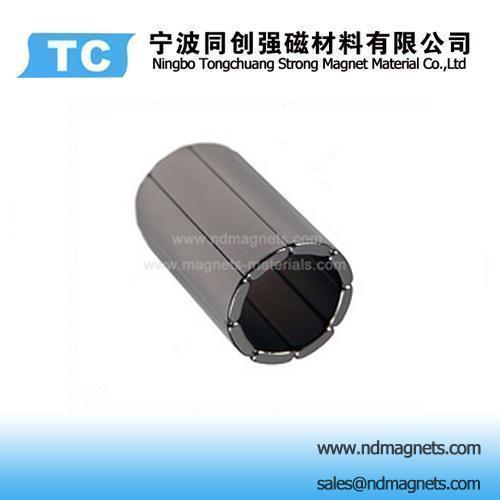

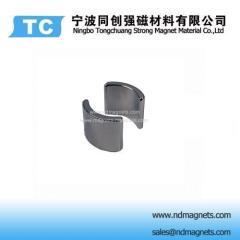

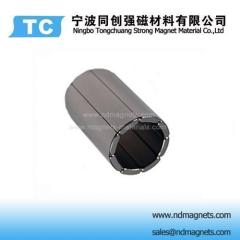

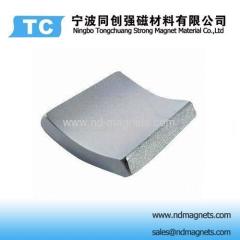

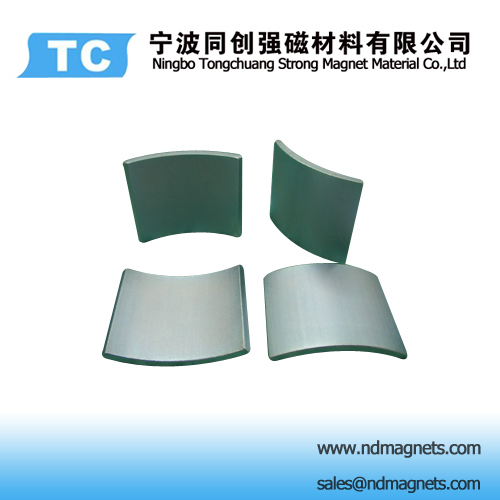

Arc magnets 45SH grade for rotors

| Price: | 0.05~10.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1.Grade 45SH

2.Customized magnets

3.Coating: NiCuNi

4,used in motors

5, High quality, low prices

Product name:45SH Grade NdFeb Magnets

Model No:ND-ARC009

45SH Grade NdFeb Magnets45SH Grade NdFeb Magnets

Magnet Property

Material:NdFeB magnet

Magnets grade :45SH

Magnets size : Customized shape.

Magnetism direction :Pare magnetized

Magnets coating : NICUNI

Max working Temperature: 150°C.

Application: rotors in motors.

| Magnetic properties of Sintered NdFeB magnets: | |||||

| Grade | Remanence | Coercive Force | Intrinsic Coercive Force | Max. energy product | Max. |

| Operating | |||||

| Temperature | |||||

| Br | Hcb | Hcj | ( BH ) | Tw | |

| max | |||||

| mT | kA/m | kA/m | kJ/m3 | ||

| (kGs) | (kOe) | (kOe) | (MGOe) | ||

| N35 | 1170-1220 | ≥ 868 | ≥ 955 | 263-287 | 80 °C |

| (11.7-12.2) | ( ≥ 10.9) | ( ≥ 12) | (33-36) | ||

| N38 | 1220-1250 | ≥ 899 | ≥ 955 | 287-310 | 80 °C |

| (12.2-12.5) | ( ≥ 11.3) | ( ≥ 12) | (36-39) | ||

| N40 | 1250-1280 | ≥ 907 | ≥ 955 | 302-326 | 80 °C |

| (12.5-12.8) | ( ≥ 11.4) | ( ≥ 12) | (38-41) | ||

| N42 | 1280-1320 | ≥ 915 | ≥ 955 | 318-342 | 80 °C |

| (12.8-13.2) | ( ≥ 11.5) | ( ≥ 12) | (40-43) | ||

| N45 | 1320-1380 | ≥ 923 | ≥ 955 | 342-366 | 80 °C |

| (13.2-13.8) | ( ≥ 11.6) | ( ≥ 12) | (43-46) | ||

| N48 | 1380-1420 | ≥ 923 | ≥ 876 | 366-390 | 80 °C |

| (13.8-14.2) | ( ≥ 11.6) | ( ≥ 12) | (46-49) | ||

| N50 | 1400-1450 | ≥ 796 | ≥ 876 | 382-406 | 80 °C |

| (14.0-14.5) | ( ≥ 10.0) | ( ≥ 11) | (48-51) | ||

| N52 | 1430-1480 | ≥ 796 | ≥ 876 | 398-422 | 60°C |

| (14.3-14.8) | ( ≥ 10.0) | ( ≥ 11) | (50-53) | ||

| 35M | 1170-1220 | ≥ 868 | ≥ 1114 | 263-287 | 100 °C |

| (11.7-12.2) | ( ≥ 10.9) | ( ≥ 14) | (33-36) | ||

| 38M | 1220-1250 | ≥ 899 | ≥ 1114 | 287-310 | 100 °C |

| (12.2-12.5) | ( ≥ 11.3) | ( ≥ 14) | (36-39) | ||

| 40M | 1250-1280 | ≥ 923 | ≥ 1114 | 302-326 | 100 °C |

| (12.5-12.8) | ( ≥ 11.6) | ( ≥ 14) | (38-41) | ||

| 42M | 1280-1320 | ≥ 955 | ≥ 1114 | 318-342 | 100 °C |

| (12.8-13.2) | ( ≥ 12.0) | ( ≥ 14) | (40-43) | ||

| 45M | 1320-1380 | ≥ 995 | ≥ 1114 | 342-366 | 100 °C |

| (13.2-13.8) | ( ≥ 12.5) | ( ≥ 14) | (43-46) | ||

| 48M | 1370-1430 | ≥ 1027 | ≥ 1114 | 366-390 | 100 °C |

| (13.7-14.3) | ( ≥ 12.9) | ( ≥ 14) | (46-49) | ||

| 50M | 1400-1450 | ≥ 1033 | ≥ 1114 | 382-406 | 100 °C |

| (14.0-14.5) | ( ≥ 13.0) | ( ≥ 14) | (48-51) | ||

| 35H | 1170-1220 | ≥ 868 | ≥ 1353 | 263-287 | 120 °C |

| (11.7-12.2) | ( ≥ 10.9) | ( ≥ 17) | (33-36) | ||

| 38H | 1220-1250 | ≥ 899 | ≥ 1353 | 287-310 | 120 °C |

| (12.2-12.5) | ( ≥ 11.3) | ( ≥ 17) | (36-39) | ||

| 40H | 1250-1280 | ≥ 923 | ≥ 1353 | 302-326 | 120 °C |

| (12.5-12.8) | ( ≥ 11.6) | ( ≥ 17) | (38-41) | ||

| 42H | 1280-1320 | ≥ 955 | ≥ 1353 | 318-342 | 120 °C |

| (12.8-13.2) | ( ≥ 12.0) | ( ≥ 17) | (40-43) | ||

| 45H | 1320-1360 | ≥ 963 | ≥ 1353 | 342-366 | 120 °C |

| (13.2-13.6) | ( ≥ 12.1) | ( ≥ 17) | (43-46) | ||

| 48H | 1370-1430 | ≥ 955 | ≥ 1353 | 366-390 | 120 °C |

| (13.7-14.3) | ( ≥ 12.5) | ( ≥ 17) | (46-49) | ||

| 35SH | 1170-1220 | ≥ 876 | ≥ 1592 | 263-287 | 150 °C |

| (11.7-12.2) | ( ≥ 11.0) | ( ≥ 20) | (33-36) | ||

| 38SH | 1220-1250 | ≥ 907 | ≥ 1592 | 287-310 | 150 °C |

| (12.2-12.5) | ( ≥ 11.4) | ( ≥ 20) | (36-39) | ||

| 40SH | 1240-1280 | ≥ 939 | ≥ 1592 | 302-326 | 150 °C |

| (12.5-12.8) | ( ≥ 11.8) | ( ≥ 20) | (38-41) | ||

| 42SH | 1280-1320 | ≥ 987 | ≥ 1592 | 318-342 | 150 °C |

| (12.8-13.2) | ( ≥ 12.4) | ( ≥ 20) | (40-43) | ||

| 45SH | 1320-1380 | ≥ 1003 | ≥ 1592 | 342-366 | 150 °C |

| (13.2-13.8) | ( ≥ 12.6) | ( ≥ 20) | (43-46) | ||

| 28UH | 1040-1080 | ≥ 764 | ≥ 1990 | 207-231 | 180 °C |

| (10.4-10.8) | ( ≥ 9.6) | ( ≥ 25) | (26-29) | ||

| 30UH | 1080-1130 | ≥ 812 | ≥ 1990 | 223-247 | 180 °C |

| (10.8-11.3) | ( ≥ 10.2) | ( ≥ 25) | (28-31) | ||

| 33UH | 1130-1170 | ≥ 852 | ≥ 1990 | 247-271 | 180 °C |

| (11.3-11.7) | ( ≥ 10.7) | ( ≥ 25) | (31-34) | ||

| 35UH | 1180-1220 | ≥ 860 | ≥ 1990 | 263-287 | 180 °C |

| (11.8-12.2) | ( ≥ 10.8) | ( ≥ 25) | (33-36) | ||

| 38UH | 1220-1250 | ≥ 876 | ≥ 1990 | 287-310 | 180 °C |

| (12.2-12.5) | ( ≥ 11.0) | ( ≥ 25) | (36-39) | ||

| 40UH | 1250-1280 | ≥ 899 | ≥ 1990 | 302-326 | 180 °C |

| (12.5-12.8) | ( ≥ 11.3) | ( ≥ 25) | (38-41) | ||

| 42UH | 1280-1320 | ≥ 899 | ≥ 1990 | 318-342 | 180 °C |

| (12.8-13.2) | ( ≥ 11.3) | ( ≥ 25) | (40-43) | ||

| 28EH | 1040-1080 | ≥ 780 | ≥ 2388 | 207-231 | 200 °C |

| (10.4-10.8) | ( ≥ 9.8) | ( ≥ 30) | (26-29) | ||

| 30EH | 1080-1130 | ≥ 812 | ≥ 2388 | 223-247 | 200 °C |

| (10.8-11.3) | ( ≥ 10.2) | ( ≥ 30) | (28-31) | ||

| 33EH | 1130-1170 | ≥ 876 | ≥ 2388 | 247-271 | 200 °C |

| (11.3-11.7) | ( ≥ 10.5) | ( ≥ 30) | (31-34) | ||

| 35EH | 1170-1220 | ≥ 876 | ≥ 2388 | 263-287 | 200 °C |

| (11.7-12.2) | ( ≥ 11.0) | ( ≥ 30) | (33-36) | ||

| 38EH | 1220-1250 | ≥ 899 | ≥ 2388 | 287-310 | 200 °C |

| (12.2-12.5) | ( ≥ 11.3) | ( ≥ 30) | (36-39) | ||

| 40EH | 1250-1280 | ≥ 899 | ≥ 2388 | 302-326 | 200 °C |

| (12.5-12.8) | ( ≥ 11.3) | ( ≥ 30) | (38-41) | ||

| 28AH | 1040-1080 | ≥ 787 | ≥ 2624 | 207-231 | 230 °C |

| (10.4-10.8) | ( ≥ 9.9) | ( ≥ 33) | (26-29) | ||

| 30AH | (1080-1130) | ≥ 819 | ≥ 2624 | 223-247 | 230 °C |

| (10.8-11.3) | ( ≥ 10.3) | ( ≥ 33) | (28-31) | ||

| 33AH | 1130-1170 | ≥ 843 | ≥ 2624 | 247-271 | 230 °C |

| (11.3-11.7) | ( ≥ 10.6) | ( ≥ 33) | (31-34) | ||

| 35AH | (1170-1220) | ≥ 876 | ≥ 2624 | 263-287 | 230 °C |

| (11.7-12.2) | ( ≥ 11.0) | ( ≥ 33) | (33-36) | ||

| 38AH | 1220-1250 | ≥ 899 | ≥ 2624 | 287-310 | 230 °C |

| (12.2-12.5) | ( ≥ 11.3) | ( ≥ 33) | (36-39) | ||

Tongchuang has staffed with a team of experienced professionals in magnetism and magnetic applications that benefits Tongchuang with many patented and unique magnet production techniques and processes. We have the patents in the products high corrosion resistance, low temperature coefficients, ultrahigh Intrinsic coefficient force (Hcj) etc. With advanced production equipments, integrated QC system and complete test equipments, all our manufacturing procedures are operated well under TS16949 and ISO 9001.

After years of market development, now our products are widely used in micro motor, automobile, medical equipment, electro-acoustic components, wind power, military aerospace, magnetic separator, and other fields. Thanks to the unique product features, production processes and quality ensuring system, our products have been exported to all over the world. Providing customers best quality products and best services is the commitment from Tongchuang. Customers' satisfaction is always the focus in our management and production activities.

ARC shape magnets used in motors

ARC shape magnets used in motors

Our advantages: 1. Original factory with professional technical and service.

2. Strict quality control systems under certification TS16949 and ISO 9001

3. Latest facilities to support R&D, quality control, process control, final product inspection

4. Very low prices due to our production well controlled , process optimization,

5, Fast lead time

6. Motto: partnership with all customers

Please specifiy the following data when you inquirying

1. Magnet size and shape, any sketch is preferable.

2.Magnet grades suitable for your application

3. plating of the magnets

4. Order quantity

5. working temperature

6. magnetized direction

7. others which may help us to quote.

.jpg)