|

Ningbo Tongchuang Strong Magnet Material Co., Ltd.

|

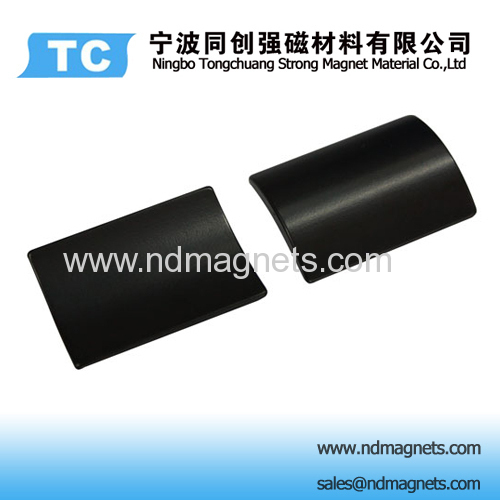

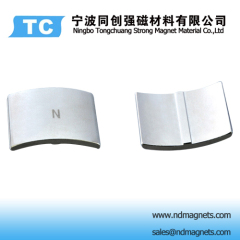

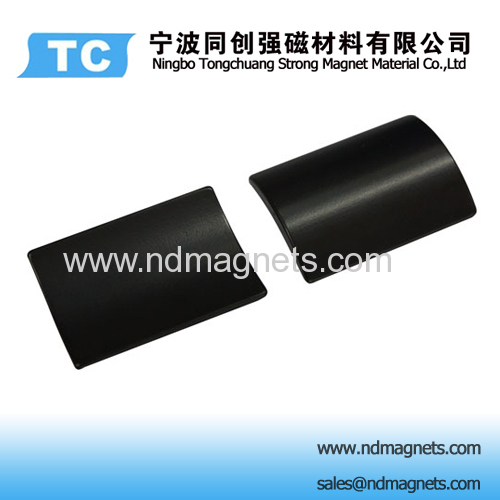

High Temperature Resistance Neodymium Arc Magnets

| Price: | 0.01~100.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P,WU |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

High temperature stability segment magnets are mainly used in car motors, EPS, brake motors, servo motors etc.

1. Motor magnets

2.Good quality

Product name:High temperature stability segment magnets

Model No:ND-ARC201

Model No:ND-ARC201

High temperature stability segment magnets

αBr: Reversible Temperature Coefficient of Br,

Br(20): Br at 20 ℃, Br(T): Br at T ℃

βHcj: Reversible Temperature Coefficient of Hcj

Hcj(20): Hcj at 20 ℃, Hcj(T): Hcj at T ℃

Usually, the industrial standards ofβHcj: is over -0.7%/℃, while theβHcj: of our developed magnet is less than -0.4%/℃, it helps our magnets with excellent temperature stability.

2. Application which needs the high temperature stability

High temperature stability magnets are mainly used in car motors, EPS, brake motors, servo motors etc.

3. Correlative temperature coefficient data

Grade Serial NO. | Conventional Formula | T-Series | L-TSeries |

αBr | -0.11~-0.128%/℃ | -0.1-0.11%/℃ | -0.09~-0.1%/℃ |

βHcj | -0.6~-0.7%/℃ | -0.55~-0.6%/℃ | -0.4~-0.55%/℃ |

Notes: TheαBr, βHcj is relative to aspect ratio, square degree chart(BH curve) etc. Higher the aspect ratio is, higher the working temperature can be. Our recommended aspect ratio is over 0.5.

The data of a certain grades, please feel free to contact us. Ordinarily, if you have the requests on αBr, βHcj, please inform the details while placing the order. Sample test is needed before mass production.

For more details, please consult our engineer.

| Magnetic properties of Sintered NdFeB magnets: | |||||

| Grade | Remanence | Coercive Force | Intrinsic Coercive Force | Max. energy product | Max. |

| Operating | |||||

| Temperature | |||||

| Br | Hcb | Hcj | (BH ) | Tw | |

| max | |||||

| mT | kA/m | kA/m | kJ/m3 | ||

| (kGs) | (kOe) | (kOe) | (MGOe) | ||

| N35 | 1170-1220 | ≥868 | ≥955 | 263-287 | 80 °C |

| (11.7-12.2) | (≥ 10.9) | (≥ 12) | (33-36) | ||

| N38 | 1220-1250 | ≥899 | ≥955 | 287-310 | 80 °C |

| (12.2-12.5) | (≥ 11.3) | (≥ 12) | (36-39) | ||

| N40 | 1250-1280 | ≥907 | ≥955 | 302-326 | 80 °C |

| (12.5-12.8) | (≥ 11.4) | (≥ 12) | (38-41) | ||

| N42 | 1280-1320 | ≥915 | ≥955 | 318-342 | 80 °C |

| (12.8-13.2) | (≥ 11.5) | (≥ 12) | (40-43) | ||

| N45 | 1320-1380 | ≥923 | ≥955 | 342-366 | 80 °C |

| (13.2-13.8) | (≥ 11.6) | (≥ 12) | (43-46) | ||

| N48 | 1380-1420 | ≥923 | ≥876 | 366-390 | 80 °C |

| (13.8-14.2) | (≥ 11.6) | (≥ 12) | (46-49) | ||

| N50 | 1400-1450 | ≥796 | ≥876 | 382-406 | 80 °C |

| (14.0-14.5) | (≥ 10.0) | (≥ 11) | (48-51) | ||

| N52 | 1430-1480 | ≥796 | ≥876 | 398-422 | 60°C |

| (14.3-14.8) | (≥ 10.0) | (≥ 11) | (50-53) | ||

| 35M | 1170-1220 | ≥868 | ≥1114 | 263-287 | 100 °C |

| (11.7-12.2) | (≥ 10.9) | (≥ 14) | (33-36) | ||

| 38M | 1220-1250 | ≥899 | ≥1114 | 287-310 | 100 °C |

| (12.2-12.5) | (≥ 11.3) | (≥ 14) | (36-39) | ||

| 40M | 1250-1280 | ≥923 | ≥1114 | 302-326 | 100 °C |

| (12.5-12.8) | (≥ 11.6) | (≥ 14) | (38-41) | ||

| 42M | 1280-1320 | ≥955 | ≥1114 | 318-342 | 100 °C |

| (12.8-13.2) | (≥ 12.0) | (≥ 14) | (40-43) | ||

| 45M | 1320-1380 | ≥995 | ≥1114 | 342-366 | 100 °C |

| (13.2-13.8) | (≥ 12.5) | (≥ 14) | (43-46) | ||

| 48M | 1370-1430 | ≥1027 | ≥1114 | 366-390 | 100 °C |

| (13.7-14.3) | (≥ 12.9) | (≥ 14) | (46-49) | ||

| 50M | 1400-1450 | ≥ 1033 | ≥1114 | 382-406 | 100 °C |

| (14.0-14.5) | (≥ 13.0) | (≥ 14) | (48-51) | ||

| 35H | 1170-1220 | ≥868 | ≥1353 | 263-287 | 120 °C |

| (11.7-12.2) | (≥ 10.9) | (≥ 17) | (33-36) | ||

| 38H | 1220-1250 | ≥899 | ≥1353 | 287-310 | 120 °C |

| (12.2-12.5) | (≥ 11.3) | (≥ 17) | (36-39) | ||

| 40H | 1250-1280 | ≥923 | ≥1353 | 302-326 | 120 °C |

| (12.5-12.8) | (≥ 11.6) | (≥ 17) | (38-41) | ||

| 42H | 1280-1320 | ≥955 | ≥1353 | 318-342 | 120 °C |

| (12.8-13.2) | (≥ 12.0) | (≥ 17) | (40-43) | ||

| 45H | 1320-1360 | ≥963 | ≥1353 | 342-366 | 120 °C |

| (13.2-13.6) | (≥ 12.1) | (≥ 17) | (43-46) | ||

| 48H | 1370-1430 | ≥955 | ≥1353 | 366-390 | 120 °C |

| (13.7-14.3) | (≥ 12.5) | (≥ 17) | (46-49) | ||

| 35SH | 1170-1220 | ≥876 | ≥1592 | 263-287 | 150 °C |

| (11.7-12.2) | (≥ 11.0) | (≥ 20) | (33-36) | ||

| 38SH | 1220-1250 | ≥907 | ≥1592 | 287-310 | 150 °C |

| (12.2-12.5) | (≥ 11.4) | (≥ 20) | (36-39) | ||

| 40SH | 1240-1280 | ≥939 | ≥1592 | 302-326 | 150 °C |

| (12.5-12.8) | (≥ 11.8) | (≥ 20) | (38-41) | ||

| 42SH | 1280-1320 | ≥987 | ≥1592 | 318-342 | 150 °C |

| (12.8-13.2) | (≥ 12.4) | (≥ 20) | (40-43) | ||

| 45SH | 1320-1380 | ≥ 1003 | ≥1592 | 342-366 | 150 °C |

| (13.2-13.8) | (≥ 12.6) | (≥ 20) | (43-46) | ||

| 28UH | 1040-1080 | ≥764 | ≥1990 | 207-231 | 180 °C |

| (10.4-10.8) | (≥ 9.6) | (≥ 25) | (26-29) | ||

| 30UH | 1080-1130 | ≥812 | ≥1990 | 223-247 | 180 °C |

| (10.8-11.3) | (≥ 10.2) | (≥ 25) | (28-31) | ||

| 33UH | 1130-1170 | ≥852 | ≥1990 | 247-271 | 180 °C |

| (11.3-11.7) | (≥ 10.7) | (≥ 25) | (31-34) | ||

| 35UH | 1180-1220 | ≥860 | ≥1990 | 263-287 | 180 °C |

| (11.8-12.2) | (≥ 10.8) | (≥ 25) | (33-36) | ||

| 38UH | 1220-1250 | ≥876 | ≥1990 | 287-310 | 180 °C |

| (12.2-12.5) | (≥ 11.0) | (≥ 25) | (36-39) | ||

| 40UH | 1250-1280 | ≥ 899 | ≥1990 | 302-326 | 180 °C |

| (12.5-12.8) | (≥ 11.3) | (≥ 25) | (38-41) | ||

| 42UH | 1280-1320 | ≥ 899 | ≥1990 | 318-342 | 180 °C |

| (12.8-13.2) | (≥ 11.3) | (≥ 25) | (40-43) | ||

| 28EH | 1040-1080 | ≥780 | ≥2388 | 207-231 | 200 °C |

| (10.4-10.8) | (≥ 9.8) | (≥ 30) | (26-29) | ||

| 30EH | 1080-1130 | ≥812 | ≥2388 | 223-247 | 200 °C |

| (10.8-11.3) | (≥ 10.2) | (≥ 30) | (28-31) | ||

| 33EH | 1130-1170 | ≥876 | ≥2388 | 247-271 | 200 °C |

| (11.3-11.7) | (≥ 10.5) | (≥ 30) | (31-34) | ||

| 35EH | 1170-1220 | ≥876 | ≥2388 | 263-287 | 200 °C |

| (11.7-12.2) | (≥ 11.0) | (≥ 30) | (33-36) | ||

| 38EH | 1220-1250 | ≥899 | ≥2388 | 287-310 | 200 °C |

| (12.2-12.5) | (≥ 11.3) | (≥ 30) | (36-39) | ||

| 40EH | 1250-1280 | ≥899 | ≥2388 | 302-326 | 200 °C |

| (12.5-12.8) | (≥ 11.3) | (≥ 30) | (38-41) | ||

| 28AH | 1040-1080 | ≥787 | ≥2624 | 207-231 | 230 °C |

| (10.4-10.8) | (≥ 9.9) | (≥ 33) | (26-29) | ||

| 30AH | (1080-1130) | ≥819 | ≥2624 | 223-247 | 230 °C |

| (10.8-11.3) | (≥ 10.3) | (≥ 33) | (28-31) | ||

| 33AH | 1130-1170 | ≥843 | ≥2624 | 247-271 | 230 °C |

| (11.3-11.7) | (≥ 10.6) | (≥ 33) | (31-34) | ||

| 35AH | (1170-1220) | ≥ 876 | ≥2624 | 263-287 | 230 °C |

| (11.7-12.2) | (≥ 11.0) | (≥ 33) | (33-36) | ||

| 38AH | 1220-1250 | ≥ 899 | ≥2624 | 287-310 | 230 °C |

| (12.2-12.5) | (≥ 11.3) | (≥ 33) | (36-39) | ||

Our advantages: 1. Original factory with professional technical and servers.

2. Strict quality control systems under certification TS16949 and ISO 9001

3. Latest facilities to support R&D, quality control, process control, final product inspection

4. Very low prices due to our production well controlled , process optimization,

5, Fast lead time

6. Motto: partnership with all customers

Production flow

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Magnets Neodymium

Ndfeb Arc Magnets

Cylinder Neodymium Magnets

Disc Neodymium Magnets

Neodymium Disc Magnets

Neodymium Magnets Block

More>>